The future is fit-to-size: the new rules of e-commerce packaging

For years, the promise of instant delivery defined the E-commerce race. Now times are changing—and fast. Today’s consumers are rethinking their priorities. They still want convenience, but they’re far more sensitive to shipping costs, sustainability, and reliability than they are to speed.

This shift is reshaping how products are delivered and how they’re packaged, handled, and protected along the way. What was once a simple operational step is now a strategic lever.

In a sector projected to grow at an average annual rate of +9.6% through 2029, understanding the evolving dynamics of packaging and logistics is critical to staying competitive. But what’s driving the change and how are the most forward-looking companies adapting?

Why fit-to-size is more than just a trend

Shipping a product in an oversized box isn’t just wasteful—it’s expensive. Carriers today use dimensional weight (DIM) pricing, where volume often trumps actual weight. That means empty space costs money.

Companies are responding by investing in fit-to-size packaging: custom boxes designed to match the product’s dimensions as closely as possible. The benefits are tangible:

- Lower shipping fees, thanks to minimized volume

- Improved load efficiency in trucks and warehouses

- Reduced use of fillers and materials, which supports recyclability

According to the DHL Rethinking Packaging Trend Report, fit-to-size strategies help businesses improve logistics KPIs while also boosting sustainability and customer satisfaction. This approach aligns operational performance with environmental impact.

Emerging technologies like automated packaging lines that scan and size products in real time are making this approach scalable. This kind of intelligent automation is becoming essential —not optional— for modern e-commerce players.

From consolidated deliveries to branded experiences

Same-day delivery used to be the ultimate promise. Now? Not so much. Studies show that 90% of online shoppers are willing to wait two to three days — if they don’t have to pay for shipping. That’s more than a trend. It’s a strategic shift.

To meet these expectations, E-commerce leaders are consolidating shipments. Today, over 50% of deliveries are multi-item orders, a move that reduces packaging waste, cuts transportation costs, and lowers emissions. Fewer boxes also mean fewer delivery attempts, easier returns, and a smoother experience for the end customer.

But what happens when that consolidated order finally lands on the doorstep? That’s where the real opportunity begins.

In a digital-first world, the package is your first physical touchpoint—your handshake, your storefront, your first impression. And with the rise of unboxing culture and eco-conscious buying habits, it has real brand power. In fact, 35% of consumers are willing to pay more for sustainable packaging and delivery.

This means that the packaging of a multi-item order is increasingly becoming a branding moment, where the box becomes a billboard for brand values: sustainability, attention to detail and product integrity.

Smart companies are investing in:

- Eco-friendly materials that resonate with green-conscious shoppers

- Premium designs that extend the brand experience beyond the screen

- Tailored structures that protect products while showcasing them beautifully

Because when a box shows up looking as good as the product inside, the message is clear: this brand gets it.

Automation: the real MVP

The volume of online orders isn’t slowing down. Labor costs are rising. Mistakes are expensive. The answer? Automation.

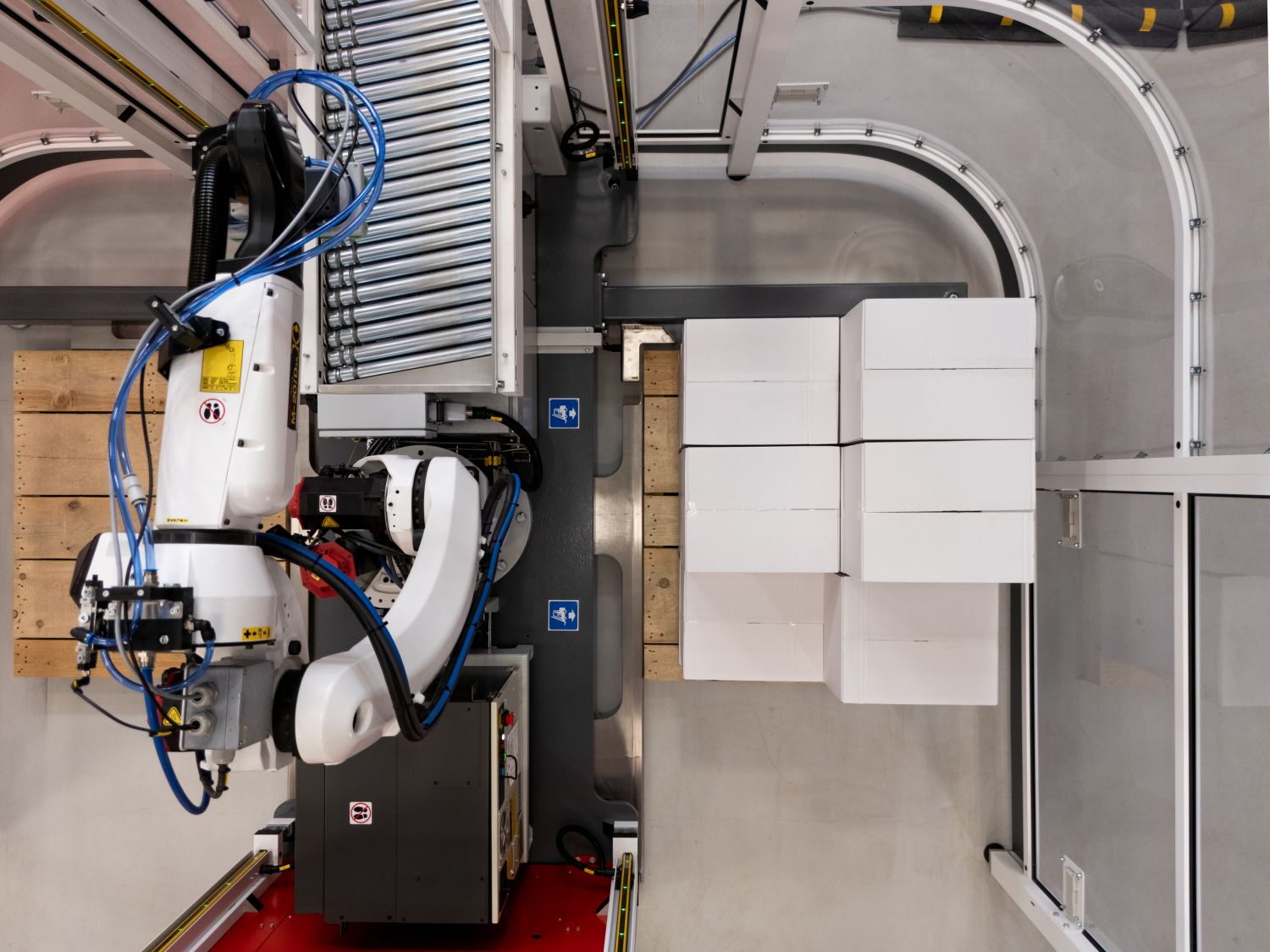

Across the e-commerce sector, fulfillment centers are increasingly investing in automated packaging systems that boost throughput, improve order accuracy, and reduce the dependency on manual labor. These systems are becoming indispensable for brands looking to scale efficiently, especially during peak seasons.

Advanced solutions—like AI-driven sorting, palletizing, modular equipment, and adaptive packaging lines—allow businesses to automate without disrupting their existing operations. By minimizing material use and optimizing every step, automation also contributes to sustainability goals while future-proofing fulfillment strategies.

Several technology providers are making this shift easier to adopt, and Coesia, among them, can offer modular systems designed to integrate into existing infrastructures, helping brands scale automation without starting from scratch.

Seamless integration: retrofitting, not rebuilding

Not every warehouse was born for E-commerce. But that doesn’t mean it can’t evolve.

Most fulfillment centers today operate in brownfield sites—spaces built before omnichannel, same-day, or AI-powered anything. And yet, they’re expected to deliver like a 2025-native operation. That’s where retrofitting comes in: not tearing down what works but enhancing it piece by piece.

Instead of investing in an entirely new facility, forward-looking companies are installing modular tech that adapts to existing layouts—from conveyors to sorting to IT. This way, automation becomes a gradual journey, not a painful leap.

Coesia understands this reality. Its approach favors integration over reinvention, offering systems that support box-first or box-last strategies, scale with demand, and slide into your infrastructure like they were there all along.

Make every box count

Gone are the days when packaging was purely functional. Today, it’s a refined expression of brand purpose and value. Custom boxes have become essential tools for expressing brand’s purpose, values, and creating a distinctive unboxing experience. Coesia’s comprehensive portfolio offers a wide array of advanced box customization solutions, elevating both the unboxing moment and the brand’s overall perception. With Coesia, packaging transforms from a simple container into a powerful asset for differentiation and customer engagement.

In a market defined by rising expectations, shrinking margins, and environmental urgency, packaging sits at the intersection of strategy, brand, and operational excellence. Only companies that embrace automation, fit-to-size solutions, and integrated systems will be able to deliver better, more memorable customer experiences.

And the best part? You don’t have to start from scratch.

You just need the right partner—and the right plan. Contact us today.