Electrode manufacturing

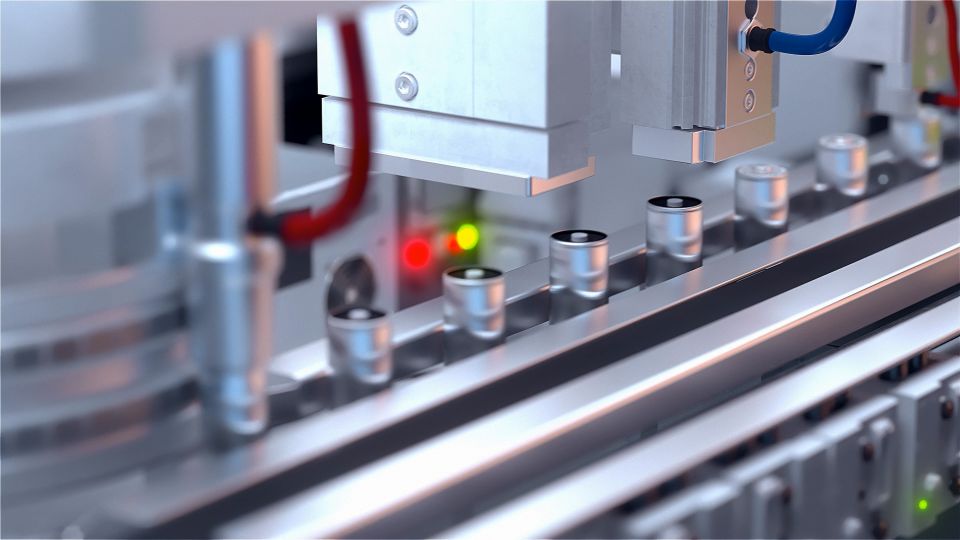

Thanks to the extensive know-how and capabilities deeply experienced in other industries, Coesia companies can apply the primary wet slurry and drying process to the electrode manufacturing.

Multiple processing machines for the wet technology can be provided with the most outperforming energy recovery system to combine efficient productivity with outstanding sustainability.

Alternative dough (dry coating) solution with a reduced footprint and lower energy and water consumption, is also available at Coesia.

Mixing, casting, drying, coating, and slitting are the innovative technologies the Group can deploy in this segment to support customers to bring value to the outcome.