Intelligent automation for a new era of e-commerce fulfillment

E-commerce logistics today operates under conditions of constant variability. Order volumes rise and fall unpredictably, assortments widen to include products of every shape and fragility and regulatory expectations around packaging and sustainability continue to intensify. What emerges is a clear requirement: fulfillment now depends on systems that combine precision in execution with flexibility in scale and intelligence in decision-making.

How does Coesia respond? By providing an integrated automation ecosystem that spans fit-to-size packaging, next-generation robotics and AI-powered palletizing. The focus is not on automating isolated steps, but on building a coherent response to the structural challenges faced by today’s operators, whether brand owners, e-commerce pure players, or third-party logistics providers.

Nine strategic challenges shaping e-commerce logistics automation

The reality of e-commerce logistics can be described through nine interconnected challenges. Understanding them provides the lens through which automation emerges as the most effective response.

1. Speed at scale

Consumers expect orders processed without delays or errors. This requires high-speed systems capable of managing pick, pack, label and dispatch stages continuously, 24/7. Manual workflows cannot scale to match sudden spikes in volume. Low-latency automation ensures real-time synchronization with omnichannel platforms, minimizing interruptions and reducing the risk of bottlenecks.

2. Dynamic fulfillment for high-mix, high-volume orders

Modern warehouses handle thousands of SKUs in varying sizes and formats. No two orders are alike. Flexibility in packaging is essential: systems must right-size parcels, remove void space and reduce dunnage. Intelligent fulfillment also allows for order-level customization (such as sustainable formats or personalized inserts) without slowing throughput.

3. Scalability to manage growth and peaks

Seasonal surges, flash sales and viral demand are now routine. Scaling with labor alone is unsustainable. Modular automation offers incremental capacity increases without redesigning the entire system. This modular deployment strategy enables operators to expand or contract in line with demand, reducing reliance on seasonal staff.

4. Labor optimization and workforce augmentation

Labor shortages and high turnover mean repetitive manual tasks can no longer form the backbone of fulfillment. Automation becomes a tool for workforce augmentation: cobots and collaborative robotics absorb strenuous, error-prone work, while employees focus on supervision, exception handling and higher-value tasks. The balance shifts from replacement to collaboration.

5. Operational efficiency and cost control

Margins in e-commerce are thin and logistics is one of the largest cost centers. Errors in labeling, mispicks, or oversized boxes multiply waste and cost. Fit-to-size packaging eliminates overpacking, lowers dimensional shipping charges and ensures material is used only where necessary. Automation reduces rework, accelerates order flow and drives down cost-per-order.

6. Sustainability and regulatory compliance

Environmental impact is under scrutiny from both consumers and regulators. Packaging must be lighter, shipments smaller and emissions lower. Automation enables this by minimizing filler materials, optimizing package size and reducing last-mile carbon footprint. The result is lower shipping costs, reduced waste and a smaller environmental footprint, benefits that directly strengthen brand reputation.

7. End-to-end process integration and visibility

Fragmentation creates blind spots: a disconnected system cannot deliver reliability. Full integration across WMS, OMS, ERP and transportation ensures every action is tracked. Real-time data enables proactive decision-making, accurate forecasting and transparency from picking to palletizing. Visibility reduces risk and strengthens customer service.

8. Intelligent automation for smarter decision-making

Speed without intelligence simply accelerates mistakes. AI-driven systems optimize sortation logic, manage mixed SKU pallets and refine routing dynamically. Self-learning algorithms improve accuracy over time, reducing error rates and anticipating shifts in product flow. Simulation tools allow operators to model future capacity scenarios before they become operational challenges.

9. Future-readiness and continuous innovation

The most dangerous limitation is obsolescence. Today’s solution must not become tomorrow’s constraint. Open architecture and modularity ensure that systems evolve in step with the business. Long-term innovation partnerships provide pathways for continuous improvement, ensuring fulfillment remains adaptive in a volatile market.

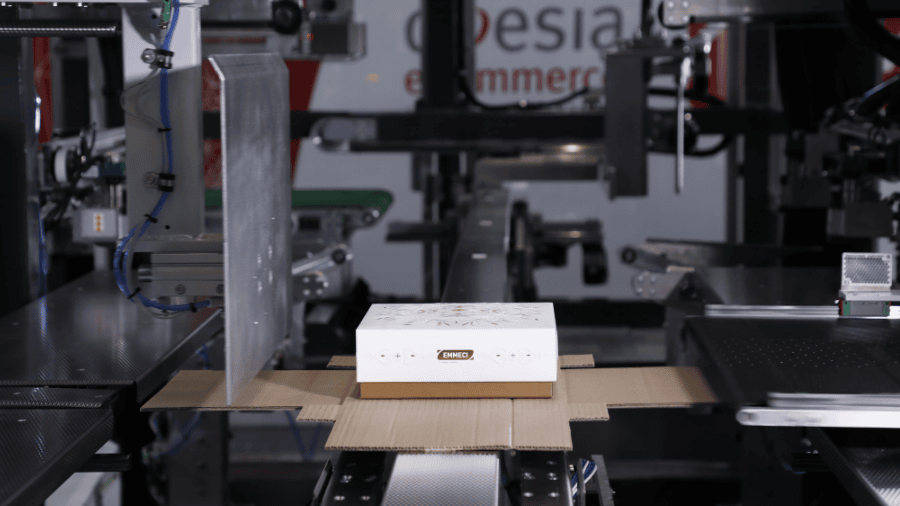

Packaging as a foundation for efficiency

One of the clearest examples of how these challenges translate into operational complexity is packaging. Frequently overlooked, it is in fact central to efficiency, and sustainability. Coesia’s packaging-on-demand solution addresses this by automating the entire chain:

Box customization: cartons or envelopes are created or selected in real time, fitting order dimensions exactly.

Graphic customization: internal and external surfaces can be digitally printed in real time, enabling branding or personalized messaging.

Automated filling: products can be mechanically inserted into the box, reducing handling time, wrong orders and manual intervention.

Sealing & closing: secure closure is applied according to process requirements, using tape, glue, or other methods depending on configuration, with the possibility of re-closable designs to support efficient returns handling.

Labeling: shipping and tracking are printed and applied automatically.

Integration: direct connection with warehouse management systems ensures consistency and traceability.

Customized documentation: invoices or personalized promotional materials can be inserted directly into the package.

The outcome is higher efficiency, consistency and scalability, with parcels that minimize void space, reduce costs and contribute to faster ROI.

Managing warehouse flow with robotics

Optimizing packaging solves one part of the equation, but the journey inside the warehouse is equally critical. To enable goods to move efficiently between picking, packing and dispatch areas, Coesia integrates advanced robotic solutions that coordinate material flow with precision and flexibility.

These systems combine compact design with high operational capacity, supporting continuous performance even in space-constrained environments.

Their modular architecture allows fulfillment centers to automate progressively, introducing robotic units step by step and adapting the level of automation to business growth without the need for a complete system overhaul.

Intelligent palletizing for complex orders

Once goods are packed and moved efficiently through the warehouse, the final step is preparing them for transport. Among the most demanding of these tasks is palletizing mixed dimensions orders. Coesia’s AI-powered Mixed Palletizer resolves this by calculating the most efficient stacking pattern in real time.

The benefits are multiple:

Maximized pallet stability for safer transport.

Increased truck fill rates and lower transportation costs.

Consistency at scale, independent of operator experience.

Here intelligence is the decisive factor that transforms palletizing from a manual art into a repeatable, data-driven process. Automation without intelligence is fast but blind; with intelligence, it anticipates and adapts.

Integration, reliability, expertise

What distinguishes Coesia’s approach is its ability to integrate packaging, robotics and AI into a single continuum, fully connected with warehouse systems. This plug-and-play integration minimizes disruption, accelerates time-to-value and allows operators to capture benefits quickly.

Equally decisive is Coesia’s foundation: decades of industrial automation expertise and proven reliability across global markets and mission-critical sectors. These qualities ensure that automation is not only innovative, but precise, durable and trusted by operators worldwide.

Coesia’s ecosystem for e-commerce

E-commerce fulfillment is defined by complexity and volatility, but automation allows operators to respond with consistency and foresight. Coesia delivers a comprehensive ecosystem (fit-to-size packaging, collaborative robotics and AI-powered palletizing) designed to meet each of the nine strategic challenges.

By combining integration, intelligence and engineering rigor, Coesia enables fulfillment centers to reduce labor dependency, optimize costs and deliver the sustainable speed customers demand.

Learn more:

Contact us to discover how Coesia can help transform your fulfillment operations.